| When constructing concrete buildings, the pour strip method is a popular way to install large concrete slabs. This process involves three segmental pours, leaving a large separation between halves in order to account for concrete shrinkage. The remaining section is then filled in to complete the pour. With the growing need for speed and quality of concrete construction, the traditional pour strip method has become time-consuming and cumbersome. At nVent LENTON, we pride ourselves on our relentless pursuit of intuitive rebar splicing solutions designed to help solve your challenges. It is with this mindset that we created the nVent LENTON Interlok Pour Strip Replacement Method. |

|

|

| Traditional Pour Strip Method DisadvantagesThe traditional pour strip method is typically a multi-month process, requiring time to cure three separate pours—ultimately slowing down job-site progress. This sizable, 4-8 foot leave-out also creates a substantial safety hazard to workers. Additionally, in large building constructions, the leave-out renders adjacent floors inaccessible. Disadvantages include:

|

nVent LENTON Interlok Pour Strip Replacement Advantages

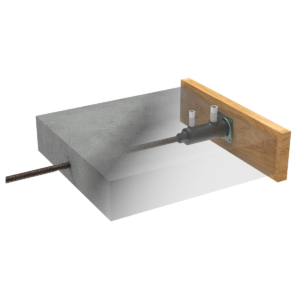

This method for concrete construction is a game-changer for constructing concrete buildings— including industrial, commercial and mixed-use projects such as data centers, hotels, hospitals and parking structures. By providing a quick and efficient manner to pour concrete and eliminating the final “closure pour”, the timeline required is drastically decreased. The 4-8 foot leave-out is reduced to a gap that is a fraction of the size at ½ inch, and can quickly be filled by nVent LENTON Interlok HY15LM Grout. With no open leave-out, construction workers can breathe easily in maximized safety conditions while maintaining full accessibility to coinciding floors.

Benefits include:

- Eliminate leave-out pours from the concrete pouring schedule

- Minimize the length of the pour process

- Reduce concrete shrinkage cracks by employing the nVent LENTON Interlok delayed grouting procedure

- Improve safety and accessibility on the job site

Get a glimpse of the side-by-side comparison and all the benefits nVent LENTON offers in the nVent LENTON Interlok Pour Strip Replacement video: https://youtu.be/pgovnmNolOw?si=rGe-TGpaSYwiYpEM

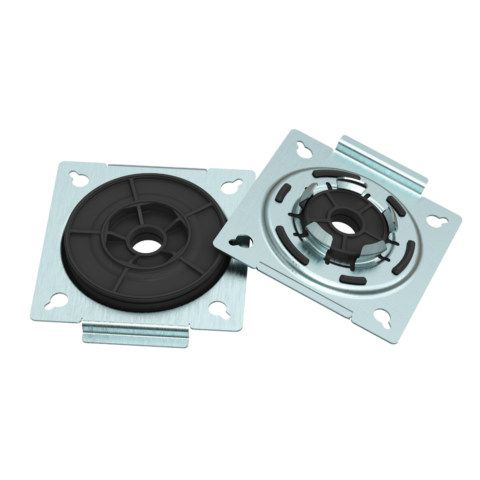

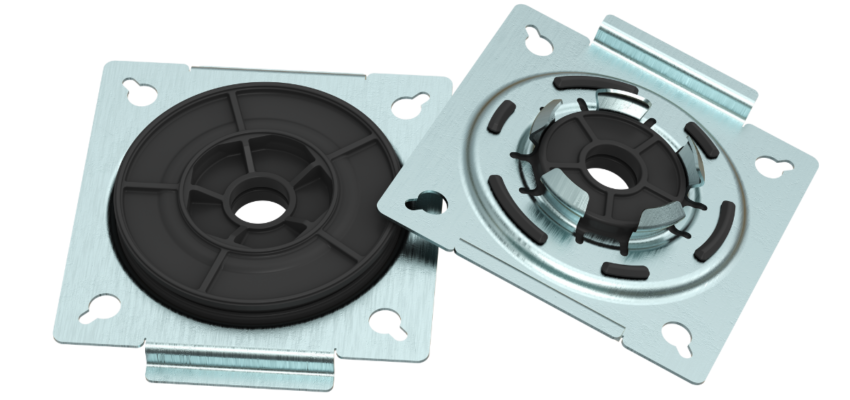

By choosing nVent LENTON Interlok products and methods, you can gain back critical time during concrete construction. This line is designed to provide structural integrity between load-bearing concrete elements such as columns, beams, shear walls, and floor slabs. nVent LENTON Interlok provides superior dynamic, seismic and ultimate strength performance for moment frame applications.

|

|

Want to learn more?

Access Brochure: https://nvent.widen.net/s/tvtw7zgqsn/cp7c-usen